Functionality Qualification (PQ): PQ concentrates on validating the system or gear’s effectiveness in the particular functioning surroundings. It consists of screening the system or tools beneath authentic-earth situations to ensure it persistently provides the meant outcomes.

Water for Injection— Water for Injection (see USP monograph) is used as an excipient within the production of parenteral together with other preparations exactly where item endotoxin content material need to be controlled, As well as in other pharmaceutical apps, for example cleaning of certain machines and parenteral solution-Get in touch with elements. The least quality of resource or feed water for your generation of Water for Injection is Consuming Water as described because of the U.S. EPA, EU, Japan, or even the WHO. This source water may very well be pre-taken care of to render it ideal for subsequent distillation (or whichever other validated system is employed based on the monograph). The completed water must meet most of the chemical necessities for Purified Water in addition to an additional bacterial endotoxin specification. Due to the fact endotoxins are made by the forms of microorganisms which have been susceptible to inhabit water, the gear and techniques employed by the system to purify, retail store, and distribute Water for Injection have to be designed to reduce or stop microbial contamination together with take out incoming endotoxin through the starting up water.

systems to filter the air during the manufacturing space (to be sure that it’s clear and will not contaminate the medicines currently being made)

Gerry Creaner has about thirty-decades of working experience during the Lifetime Sciences Production sector across A variety of complex, managerial and organization roles. He recognized an exceptionally prosperous engineering consultancy just before founding GetReskilled, an internet based schooling and Mastering organization, with workplaces in Singapore, Eire and Boston (United click here states of america), focussed around the manufacture of Harmless and efficient medicines for the general public.

The design approval is a vital milestone within a undertaking as it causes it to be possible to progress with manufacturing and programming. To achieve an approval it is necessary to assessment all style and design documents and drawings In keeping with the requirements (Figure 2).

The essential steps in validating various water systems, and once They're validated, setting up a routine checking method to take care of them are talked over.

With modern limited time schedules, a Fats is incredibly handy for the new set up of the plant. The gain is the fact that premanufactured units are checked and analyzed just as much as possible ahead of These are despatched to web-site.

This calculation demonstrates that the provider can get paid a major gain. As revealed in Figure 4, the total return on investment for your cell device in excess of its overall lifetime can attain more than €1 million.

At the time here PPQ has actually been handed, the medicines through the new manufacturing facility can be found available for sale to people (i.e. industrial distribution). All thriving batches of medicines designed throughout the PPQ phase can also be permitted to be distributed commercially.

Any modification with respect towards the accepted style and design, necessities shall be identified, and the exact same is stated to The seller and documented as minutes of the meeting duly signed by Consumer, QA Job/Engineering, and Vendor.

We’ll also Be certain that we’re retaining our baking devices – we’ll retain our oven cleanse, we’ll routinely calibrate our weighing scales, and we’ll replace pieces inside our mixer because they’re required.

This stage makes sure that the devices capabilities as meant in the event the substances to generate the medication are utilized (not only water).

We’ll have them dress in the aprons as well as hair nets that they’ll should after we commence advertising our cakes.

OQ verifies the products features within specified operational limitations, performs expected responsibilities precisely, and fulfills predefined performance criteria.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Shane West Then & Now!

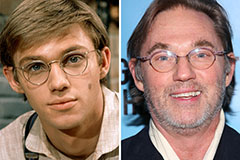

Shane West Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!